My apartment in Downtown Austin has officially become a manufacturing facility!!

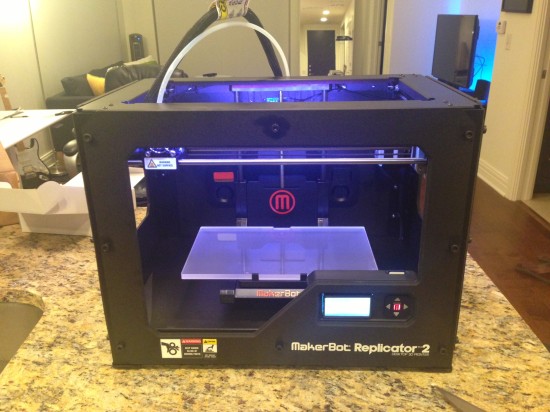

I got my new MakerBot Replicator 3D printer and setup it up this week. Here it is sitting on my kitchen counter:

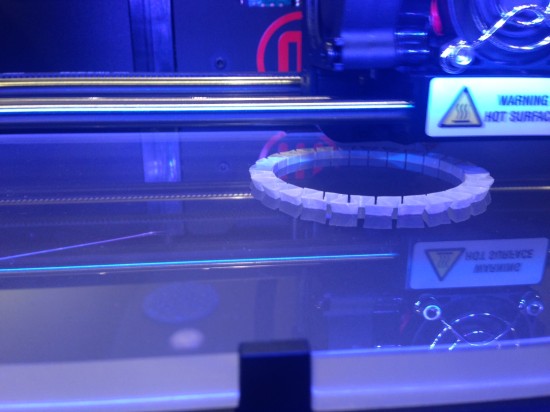

After setting it up and handling a few minor technical issues, I tried firing it up and printing something that was on the included SD card. First thing I printed was this stretchy bracelet. Here it is layer-by-layer being printed out in PLA plastic:

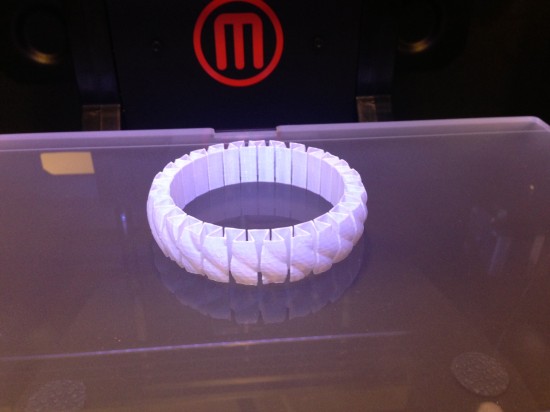

Finished product. Took a little less than 15 minutes to fully print:

Take it off the built plate and it’s ready to wear! That’s what I liked about the MakerBot Replicator2….it doesn’t have any messy cleanup process (a lot of 3D printers use powder or plastic-resin to make stuff which has to be cleaned off). It’s super sturdy and can be stretched:

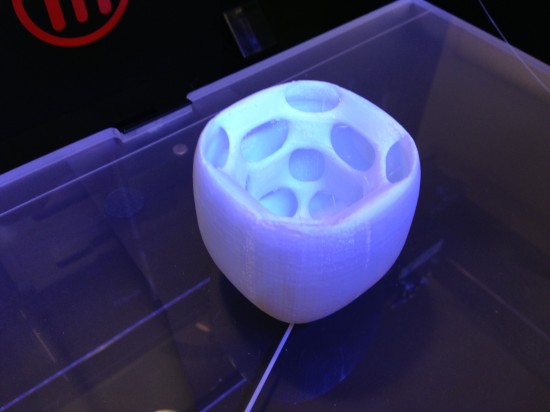

Like I previously wrote, I wanted to print something that couldn’t be made through most manufacturing processes, so I printed a 3D shot glass! It’s got this internal structure that’s useless, but makes the shot glass look cool and “3D printed”.

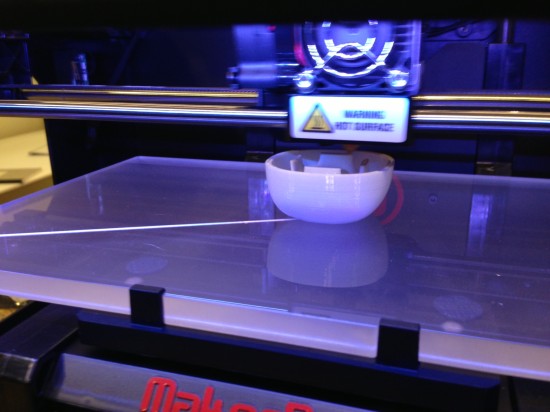

Here it is halfway printed:

Finished product:

Ready to drink!

I was shocked by how sturdy the shot glass came out. The settings were on super high quality, so it took 1 1/2 hours to print, but the build was extraordinarily strong. I doubt you could even smash that thing with a hammer (I tried and failed). Very impressive strength.

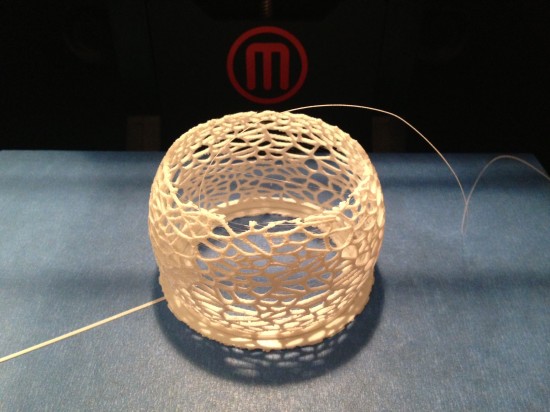

Next thing I printed was this cool looking candle cover. Here it is fresh out of the printer:

Stick a tea-candle in the middle and it gives off this cool effect……and I manufactured this thing in my APARTMENT!!

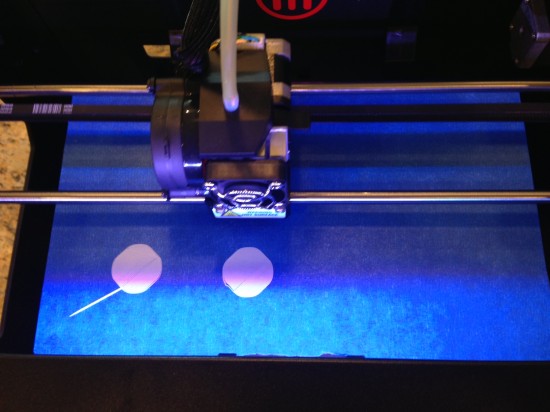

The next step was to see how long some real “manufacturing” would take. So before running out of the house for a few hours, I quickly added some random items to a file and hit ‘print’.

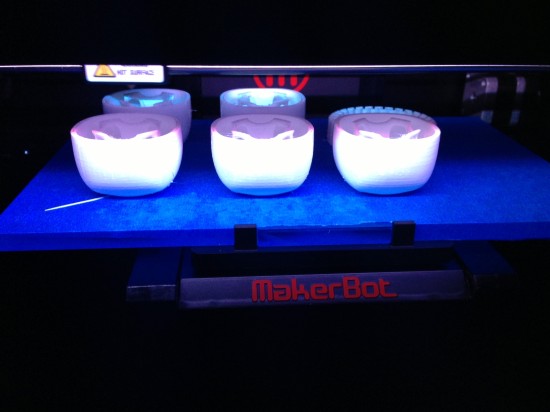

I put 5 3D shot glasses, and 1 stretchy bracelet, hit ‘print’ and ran out of the house. Here was the very beginning phases of the print:

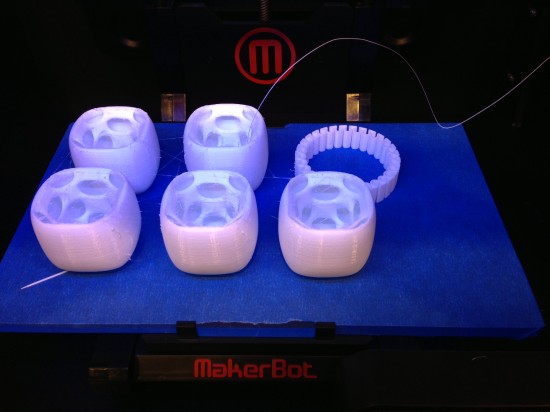

After a few hours (I left the settings on super-high…..so the print took longer than it should have):

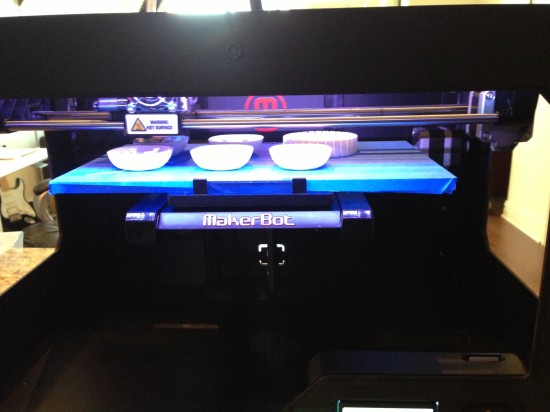

Almost finished:

8 hours after hitting ‘print’ these were waiting for me at home:

Overall I’m super impressed with this thing. I mean, the technology still sucks right now compared to what it’ll be in the future (being able to print circuits and whatnot), but this is an awesome learning experience.

I quickly learned to use the MakerWare software for loading objects to print…it’s super-simple.

Now I’m going to start learning some 3D modeling using Blender. That will be a tad bit harder, but more rewarding since I’ll be able to make my OWN things and print/share them.

So far this has been fun :)

Cheers!

-Neville Medhora